Synthetic Diamond

Definition and Basic Principle

- Definition: Synthetic diamond refers to diamond crystals that are artificially manufactured by simulating the environment and conditions under which natural diamonds are formed. It has basically the same chemical composition (mainly carbon element), crystal structure, and physicochemical properties as natural diamonds.

- Principle: Under high temperature and high pressure environments (for example, in the high-pressure high-temperature method, usually requiring a high temperature above 1000 °C and tens of thousands of atmospheres), or by using the chemical vapor deposition (CVD) method, carbon atoms are made to crystallize and grow in a specific arrangement to form a diamond structure. For instance, the high-pressure high-temperature method simulates the high-temperature and high-pressure state inside the earth when natural diamonds are formed, prompting carbon atoms to aggregate and crystallize. While the CVD method decomposes carbon-containing gases (such as methane, etc.) to deposit carbon atoms layer by layer on a substrate under relatively low temperature and low pressure conditions to grow diamond crystals.

Manufacturing Methods

- High-Pressure High-Temperature Method (HPHT)

- Characteristics: This is a relatively traditional method for synthesizing diamonds. Graphite or other carbon-containing materials are used as the carbon source and placed in special metal catalysts (such as iron, nickel and other metals). Then they are put into a high-temperature and high-pressure device (like a cubic press and other equipment). After a certain period of processing, carbon atoms are rearranged under the action of the catalyst and crystallize to form diamonds.

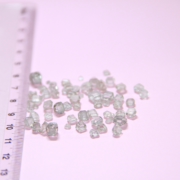

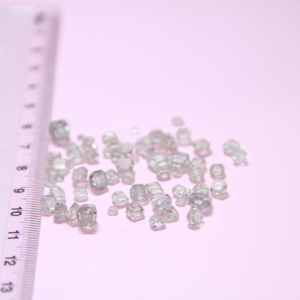

- Applications: It is often used to produce industrial diamonds. For example, diamond abrasives for cutting, grinding and other processing industries can be manufactured. Because it can mass-produce small-sized diamonds with hardness and other properties meeting industrial requirements. It can also produce gem-quality synthetic diamonds of a certain size and quality, although it is relatively difficult to control aspects such as color.

- Chemical Vapor Deposition Method (CVD)

- Characteristics: It is a synthesis method carried out under relatively mild conditions (compared with the high-pressure high-temperature method, the temperature is usually several hundred degrees Celsius to more than 1,000 degrees Celsius, and the pressure is close to normal pressure). Carbon-containing gases are decomposed into carbon atoms under the excitation of an energy source (such as microwaves, plasma, etc.), and then deposited on a substrate (such as a silicon wafer, etc.) to slowly grow into diamond films or thick diamond crystals. It can more accurately control the growth layers, doping impurities and other situations of diamonds, so that the color, electrical properties and other aspects of diamonds can be well regulated.

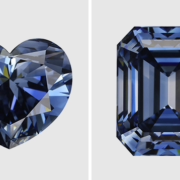

- Applications: It is increasingly widely used in the preparation of high-quality gem-quality synthetic diamonds. It can grow large-sized, high-clarity diamonds with adjustable colors as required. At the same time, in the field of electronics, it can be used to manufacture diamond semiconductors and other materials with special electrical properties, such as manufacturing high-frequency, high-power electronic devices based on diamond.

Differences from and Identification of Natural Diamonds

- Differences:

- Internal Features: During the formation process of natural diamonds, various natural inclusions will be included, such as mineral crystal inclusions, fractures, etc. The types, shapes and distributions of these inclusions are random. However, the internal features of synthetic diamonds are often related to their synthesis methods. For example, metal catalyst inclusions may appear in diamonds synthesized by the high-pressure high-temperature method, showing specific shapes and distribution patterns. Diamonds synthesized by the CVD method may have growth striations and other features, and some CVD diamonds may have different fluorescence performances under ultraviolet light irradiation.

- Growth Textures: The growth textures of natural diamonds are relatively natural and complex, which are unique marks formed over a long geological period. The growth textures of synthetic diamonds are relatively regular and have a certain directionality. For example, CVD diamonds have layered texture features along the growth direction.

- Identification Methods:

- Detection by Professional Instruments: Commonly used diamond detectors, for example, detect a variety of physical properties such as the optical and electrical properties of diamonds to distinguish them. For instance, using a Raman spectrometer, there are slight differences in spectral characteristics between natural diamonds and synthetic diamonds. The position and intensity of the Raman peaks can reflect the crystallization situation of diamonds and whether they are synthetic or not. There are also fluorescence spectrometers. When excited by specific wavelengths of light, natural diamonds and synthetic diamonds have different fluorescence wavelengths, intensities, distributions, etc., which can assist in identification.

- Observation Method (for Experienced Personnel): Through professional magnifying glasses (such as 10x magnifying glasses) or microscopes to observe the internal features, surface features and growth textures of diamonds. Experienced appraisers can find some typical signs of synthetic diamonds. However, the accuracy of this method is relatively limited and needs to be combined with instrument detection for comprehensive judgment.

Uses

- Jewelry Field: Because its appearance is extremely similar to that of natural diamonds and its price is relatively low, gem-quality synthetic diamonds are increasingly used to make various jewelry items such as rings, necklaces, earrings, etc., providing consumers with more beautiful and cost-effective choices.

- Industrial Field: Relying on the super-hard physical properties of diamonds, synthetic diamonds are widely used in processing industries such as cutting, grinding, and drilling. For example, they are used to cut stone materials and process metal parts, which greatly improves processing efficiency and quality. In the optical field, they can be used to manufacture high-precision optical windows, lenses, etc., taking advantage of their high transparency and high hardness. In the electronics field, synthetic diamond semiconductor materials are expected to play an important role in future high-speed communications, high-power electronic equipment, etc., such as manufacturing high-frequency, low-loss transistors.

In conclusion, synthetic diamonds have an important position and broad application prospects in multiple fields. With the continuous development of technology, their quality and performance are also constantly improving.

Leave a Reply

Want to join the discussion?Feel free to contribute!