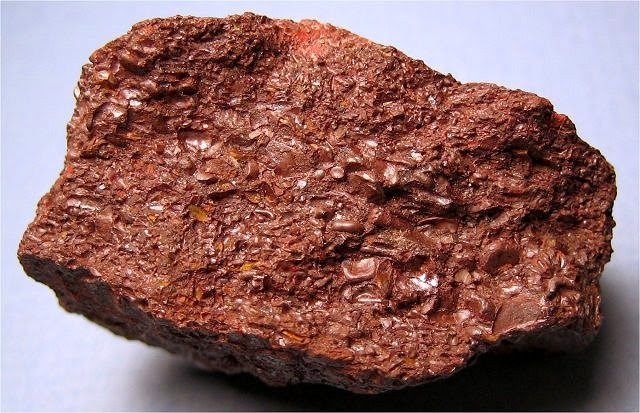

Iron (Fe) Ore

Iron ore is a type of rock or mineral from which metallic iron can be extracted economically. It typically contains iron compounds in the form of oxides, carbonates, or sulfides, along with various impurities. The characteristics of iron ore can vary depending on the type of ore, but generally include:

- Composition: Iron ore is primarily composed of iron, usually in the form of iron oxides such as hematite (Fe2O3), magnetite (Fe3O4), or goethite (FeO(OH)). It may also contain other elements or minerals as impurities, such as silica, alumina, phosphorus, sulfur, and trace elements.

- Physical properties: Iron ore is usually hard, dense, and heavy. The color can vary depending on the type of iron oxide present, with hematite typically being red or reddish-brown, magnetite being black or dark gray, and goethite being brown or yellowish-brown. Iron ore can have various textures, including crystalline, granular, or massive.

- Ore grade: The iron content, or iron grade, of iron ore is an important characteristic. High-grade iron ore typically contains a higher percentage of iron, which makes it more valuable and desirable for iron and steel production.

- Mineralogy: Different types of iron ore minerals have distinct mineralogical characteristics, such as crystal structure, mineral associations, and mineral liberation. These mineralogical properties can affect the processing and beneficiation of iron ore.

- Occurrence: Iron ore can occur in various geological settings, including sedimentary, metamorphic, and igneous rocks. It can also be found in different forms, such as vein deposits, bedded deposits, and disseminated deposits, which can impact the mining and extraction methods used.

- Accessibility and location: The accessibility and geographic location of iron ore deposits can impact their economic viability and transportation costs. Iron ore deposits that are close to transportation routes or infrastructure, such as ports or railways, are generally more desirable for mining and processing.

- Impurities: Iron ore may contain various impurities, such as silica, alumina, phosphorus, sulfur, and trace elements, which can affect the quality and suitability of the ore for iron and steel production. The presence of impurities may require additional processing or beneficiation steps to remove or reduce them.

Overall, iron ore is a valuable raw material for the production of iron and steel, and its characteristics can vary depending on the type of ore, mineralogy, grade, occurrence, and impurities present. Understanding the definition and characteristics of iron ore is important for its exploration, mining, processing, and utilization in various industries.

Contents

- Historical and modern uses of iron and iron products

- Description and properties of common iron ore minerals

- Examples of iron-bearing minerals and their occurrences

- Differences between hematite, magnetite, and other iron ore minerals

- Occurrence and Distribution of Iron Ore Worldwide

- Types of iron ore deposits and their characteristics

- Mining and Processing

- Uses of Iron Ore and Iron Products

- Market Trends and Challenges in the Iron Ore Industry

- Summary of Key Points about

Historical and modern uses of iron and iron products

Iron has been used by humans for thousands of years and has played a critical role in the development of human civilization. The historical and modern uses of iron and iron products include:

Historical uses of iron:

- Tools and weapons: Iron was first used by early humans to create tools and weapons, such as knives, spears, and arrowheads, which revolutionized hunting, farming, and warfare.

- Construction: Iron was used in ancient times to construct buildings, bridges, and other structures, providing increased strength and durability compared to other materials.

- Transportation: Iron was used in the construction of carts, wagons, and ships, enabling the transportation of goods and people over longer distances.

- Art and ornamentation: Iron was used in ancient metalworking to create decorative and artistic objects, such as sculptures, jewelry, and coins.

Modern uses of iron:

- Steel production: Iron is a key ingredient in the production of steel, which is used in a wide range of modern applications, including construction, transportation, machinery, appliances, and packaging. Steel is a versatile and widely used material due to its strength, durability, and versatility.

- Automotive industry: Iron and steel are used extensively in the manufacturing of automobiles and other vehicles, including body frames, engines, transmissions, suspension systems, and wheels.

- Infrastructure and construction: Iron and steel are used in the construction of buildings, bridges, roads, railways, and other infrastructure projects due to their strength, durability, and load-bearing capacity.

- Machinery and equipment: Iron and steel are used in the manufacturing of machinery and equipment for various industries, including manufacturing, agriculture, mining, and energy production.

- Packaging and containers: Iron and steel are used in the manufacturing of cans, containers, and packaging materials, providing a durable and protective solution for storing and transporting goods.

- Household appliances: Iron and steel are used in the manufacturing of household appliances, such as refrigerators, stoves, washing machines, and dishwashers, due to their strength, heat resistance, and durability.

- Energy production: Iron and steel are used in the manufacturing of equipment for energy production, including wind turbines, solar panels, and power transmission lines.

- Medical and pharmaceutical applications: Iron and iron-based compounds are used in various medical and pharmaceutical applications, such as in the production of medicines, dietary supplements, and medical devices.

The uses of iron and iron products have evolved over time and continue to play a crucial role in modern society across a wide range of industries and applications.

iron ore mineral

iron ore mineral

Description and properties of common iron ore minerals

Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted. Common iron ore minerals include:

- Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral. It is typically steel-gray to black in color and has a metallic luster. Hematite is often found as massive, botryoidal, or reniform (kidney-shaped) formations. It has a high iron content of around 70%, making it an important source of iron for steel production. Hematite is hard and relatively dense, with a specific gravity ranging from 4.9 to 5.3.

- Magnetite (Fe3O4): Magnetite is another important iron ore mineral, known for its magnetic properties. It is usually black or dark brown in color and has a metallic luster. Magnetite is often found in octahedral or dodecahedral crystals, as well as in granular, massive, or crystalline forms. It has a high iron content, typically ranging from 60% to 70%. Magnetite is magnetic, and its presence can be detected using a magnet. It has a specific gravity ranging from 4.9 to 5.3.

- Limonite (FeO(OH)·nH2O): Limonite is a yellowish-brown iron ore mineral that forms as a result of weathering and hydration of other iron-bearing minerals, such as hematite and magnetite. Limonite is typically amorphous or earthy in texture, and it often contains goethite (FeO(OH)) as an impurity. Limonite has a lower iron content compared to hematite and magnetite, usually ranging from 40% to 60%. It has a relatively low specific gravity, typically ranging from 2.7 to 4.3.

- Siderite (FeCO3): Siderite is a carbonate iron ore mineral that is typically brownish-yellow to grayish-white in color. It often forms as a result of hydrothermal processes or weathering of other iron-bearing minerals. Siderite has a lower iron content, usually ranging from 30% to 48%. It has a relatively low specific gravity, typically ranging from 3.7 to 4.0.

- Goethite (FeO(OH)): Goethite is a common iron ore mineral that is often found in association with hematite and other iron-bearing minerals. It is typically yellow, brown, or reddish-brown in color and has a fibrous or earthy texture. Goethite is an important source of iron, but its iron content is lower compared to hematite and magnetite.

- Chamosite (Fe2+5Al)(AlSi3O10)(OH)8: Chamosite is a greenish-gray iron-bearing mineral that is a member of the chlorite group. It is often found in iron ore deposits associated with other iron minerals such as hematite and magnetite. Chamosite has a relatively low iron content and is not a major source of iron for steel production, but it may contribute to the overall iron content of an ore deposit.

- Taconite: Taconite is a type of iron formation that is found primarily in the United States, particularly in the Lake Superior region. It is a sedimentary rock that contains a mixture of iron-bearing minerals, including hematite, magnetite, goethite, and others. Taconite is a lower-grade iron ore compared to hematite and magnetite, and it requires extensive processing to extract iron for steel production.

- Martite (hematite pseudomorph after magnetite): Martite is a pseudomorph mineral that forms when magnetite is replaced by hematite through a process known as pseudomorphism. It retains the shape and structure of magnetite but has a composition of hematite. Martite is often found in iron ore deposits where magnetite has been partially or completely replaced by hematite, and it may be an important source of iron in such deposits.

- Maghemite (γ-Fe2O3): Maghemite is a rare iron oxide mineral that is often found in association with other iron minerals in iron ore deposits. It is similar in composition to hematite but has a different crystal structure. Maghemite is typically found in weathered or altered iron ore deposits and may have a reddish-brown or black color. It is not a major source of iron for steel production but may contribute to the overall iron content of an ore deposit.

These are some of the common iron ore minerals that are mined and processed for the production of iron and steel. The properties of these minerals, such as their color, luster, texture, and iron content, are important factors in their identification, extraction, and utilization in various industrial processes.

Iron ores Magnetite

Iron ores Magnetite

Examples of iron-bearing minerals and their occurrences

Iron-bearing minerals occur in various geological settings around the world. Some examples of iron-bearing minerals and their occurrences include:

- Hematite (Fe2O3): Hematite is a common iron oxide mineral and is the most important iron ore mineral. It occurs in many different geological environments, including sedimentary, metamorphic, and igneous rocks. Hematite is found in large quantities in iron ore deposits such as the Pilbara region of Western Australia, the Mesabi Range in Minnesota, USA, and the Carajás mine in Brazil.

- Magnetite (Fe3O4): Magnetite is a magnetic iron oxide mineral that is commonly found in igneous and metamorphic rocks, as well as in some sedimentary rocks. It occurs in various iron ore deposits around the world, including the Kiruna mine in Sweden, the Labrador Trough in Canada, and the Kursk Magnetic Anomaly in Russia.

- Goethite (FeO(OH)): Goethite is an iron oxide hydroxide mineral that often occurs as a weathering product of other iron-bearing minerals, such as hematite and magnetite. It is typically found in soil and sedimentary environments, as well as in some ore deposits. Goethite is widespread and can be found in many countries, including Australia, Brazil, India, and the United States.

- Pyrite (FeS2): Pyrite is a common iron sulfide mineral that occurs in a wide range of geological settings, including sedimentary, metamorphic, and igneous rocks. While not a major source of iron for industrial purposes, pyrite can sometimes be found in iron ore deposits as an associated mineral. Pyrite is found in many countries, including the United States, Spain, Russia, and China.

- Chamosite (Fe2(Mg,Fe)5Al)(AlSi3O10)(OH)8: Chamosite is a greenish iron-magnesium silicate mineral that is often associated with iron ore deposits, particularly in sedimentary rocks. It occurs in various countries, including France, the United States, and Brazil.

These are just a few examples of iron-bearing minerals and their occurrences. Iron-bearing minerals can be found in a wide range of geological settings, and their distribution depends on factors such as geological history, mineralization processes, and local geology. The identification and understanding of these minerals are important in the exploration, extraction, and utilization of iron ore resources.

Iron ore

Iron ore

Differences between hematite, magnetite, and other iron ore minerals

Hematite, magnetite, and other iron ore minerals differ in several key aspects, including their chemical composition, crystal structure, physical properties, and occurrences. Here are some of the main differences:

- Chemical composition: Hematite is an iron oxide mineral with the chemical formula Fe2O3, while magnetite is an iron oxide mineral with the chemical formula Fe3O4. Other iron ore minerals, such as goethite, pyrite, and chamosite, have different chemical compositions and may contain additional elements, such as aluminum, magnesium, and sulfur.

- Crystal structure: Hematite has a rhombohedral crystal structure, while magnetite has a cubic crystal structure. This difference in crystal structure affects their physical properties, such as their magnetic and electrical properties.

- Magnetic properties: Hematite is typically not magnetic, while magnetite is strongly magnetic. This difference in magnetic properties is one of the key distinguishing features between hematite and magnetite, and it has important implications for their separation and beneficiation in iron ore processing.

- Physical properties: Hematite is typically dark red or brownish in color, with a reddish streak, and has a hardness of 5.5-6.5 on the Mohs scale. Magnetite is usually black or dark brown in color, with a black streak, and has a hardness of 5.5-6.5. Other iron ore minerals, such as goethite, pyrite, and chamosite, may have different colors, streaks, and hardness values.

- Occurrences: Hematite and magnetite are the two most important iron ore minerals and are commonly found in iron ore deposits worldwide. Hematite is often associated with sedimentary rocks, while magnetite can occur in a wider range of geological settings, including igneous, metamorphic, and sedimentary rocks. Other iron ore minerals, such as goethite, pyrite, and chamosite, may also occur in various geological environments, but their occurrences are typically more localized and associated with specific geological processes.

- Economic importance: Hematite and magnetite are the most important iron ore minerals due to their high iron content and widespread occurrences, and they are extensively mined and processed for the production of iron and steel. Other iron ore minerals, such as goethite, pyrite, and chamosite, may also have economic value, but their contributions to the global iron ore production are relatively small.

These are some of the main differences between hematite, magnetite, and other iron ore minerals. Understanding the characteristics and properties of these minerals is important in the exploration, extraction, and processing of iron ore resources for various industrial applications.

Occurrence and Distribution of Iron Ore Worldwide

Iron ore is a widely distributed mineral resource that occurs in various geological settings worldwide. Here are some key points about the occurrence and distribution of iron ore:

- Major iron ore-producing countries: The leading iron ore-producing countries in the world are Australia, Brazil, China, India, Russia, and South Africa, which collectively account for the majority of global iron ore production. Other significant iron ore-producing countries include Canada, Ukraine, United States, Sweden, Iran, and Kazakhstan, among others.

- Geological settings: Iron ore deposits can occur in a variety of geological settings, including sedimentary, igneous, and metamorphic rocks. The most common type of iron ore deposit is the banded iron formation (BIF), which is a sedimentary rock that consists of alternating layers of iron-rich minerals (such as hematite or magnetite) and chert or other silica-rich minerals. Iron ore can also occur in igneous rocks as titanomagnetite and vanadiferous magnetite deposits, as well as in metamorphic rocks as metamorphosed iron formations or skarn deposits.

- Occurrence in sedimentary rocks: Banded iron formations (BIFs) are the most significant sedimentary rocks hosting iron ore deposits. BIFs are found in a variety of geological settings, including lake, marine, and fluvial environments. Some of the largest iron ore deposits in the world, such as those in the Pilbara region of Western Australia, are hosted in BIFs.

- Occurrence in igneous rocks: Iron ore deposits can also occur in igneous rocks, particularly in association with mafic and ultramafic intrusions. These deposits are commonly referred to as titanomagnetite deposits due to the presence of titanium and magnetite minerals. Examples of titanomagnetite deposits include the Kiruna deposit in Sweden and the Bushveld Complex in South Africa.

- Occurrence in metamorphic rocks: Iron ore can also be found in metamorphic rocks that have undergone high-pressure and high-temperature conditions. These iron ore deposits are typically associated with skarns, which are contact metamorphic rocks that form at the contact between intrusions and carbonate-rich rocks. Skarn deposits are relatively small compared to BIFs and titanomagnetite deposits, but they can be economically important sources of iron ore.

- Distribution patterns: The distribution of iron ore deposits around the world is not uniform and varies depending on geological, economic, and geopolitical factors. For example, Australia and Brazil are major iron ore producers due to their large BIF-hosted deposits, while China and India are significant producers due to their vast reserves of hematite and magnetite ores. Other countries may have smaller deposits or limited resources of iron ore, but still contribute to global production.

Understanding the occurrence and distribution of iron ore worldwide is crucial for the exploration, evaluation, and exploitation of iron ore resources for various industrial applications, particularly for the production of iron and steel, which are essential materials for modern society.

Global iron ore industry

Global iron ore industry

Types of iron ore deposits and their characteristics

There are several types of iron ore deposits, each with its own characteristics. Some of the major types of iron ore deposits include:

- Banded Iron Formation (BIF): BIFs are sedimentary rocks that consist of alternating bands of iron-rich minerals, such as hematite or magnetite, and chert or other silica-rich minerals. BIFs are the most significant type of iron ore deposit and are typically found in Precambrian-age rocks. They can be extensive in size and are known for their high-grade iron ore content.

- Magnetite Deposits: Magnetite is an iron oxide mineral that can occur in igneous, metamorphic, and sedimentary rocks. Magnetite deposits are often associated with mafic and ultramafic intrusions, and can also form as skarn deposits at the contact between intrusions and carbonate-rich rocks. Magnetite deposits are known for their high iron content and can be economically important sources of iron ore.

- Hematite Deposits: Hematite is an iron oxide mineral that is widely distributed and occurs in a variety of geological settings. Hematite deposits can be found in sedimentary, igneous, and metamorphic rocks. They are typically associated with BIFs, but can also occur as residual or enriched deposits formed by weathering and erosion of iron-rich rocks. Hematite deposits are often lower in iron content compared to magnetite deposits, but can still be economically viable sources of iron ore.

- Goethite and Limonite Deposits: Goethite and limonite are iron oxide minerals that are commonly associated with weathering of iron-rich rocks and can form deposits known as laterites. Laterite deposits are typically found in tropical and subtropical regions where intense weathering has occurred. They are characterized by their high moisture content and low iron content, and are typically considered lower-grade iron ore deposits.

- Carbonate-Hosted Iron Deposits: Carbonate-hosted iron deposits, also known as sedimentary-exhalative (SEDEX) iron deposits, are formed by precipitation of iron minerals from hydrothermal fluids in sedimentary basins. These deposits are characterized by their association with carbonate rocks and can contain significant iron ore resources.

- Skarn Deposits: Skarn deposits are formed at the contact between intrusions and carbonate-rich rocks, and can contain iron ore minerals as well as other valuable minerals. Skarn deposits are typically smaller in size compared to other types of iron ore deposits, but can still be economically viable sources of iron ore.

Each type of iron ore deposit has its own unique characteristics in terms of geology, mineralogy, and economic potential. Understanding the different types of iron ore deposits is important for exploration, evaluation, and mining of iron ore resources, as it helps determine the appropriate mining and processing methods, and the quality and quantity of iron ore that can be extracted from a particular deposit.

Iron ore deposits

Iron ore deposits

Mining and Processing

Mining and processing of iron ore involve several stages, including exploration, development, extraction, beneficiation, and transportation. The overall process can vary depending on the type of iron ore deposit, its location, and the economics of extraction.

- Exploration: The first stage in mining iron ore is exploration, which involves identifying and evaluating potential iron ore deposits. This typically involves geological mapping, sampling, and geophysical surveys to locate areas with high iron content.

- Development: Once a potential iron ore deposit is identified, the next stage is development. This involves conducting detailed studies and assessments to determine the economic viability of the deposit. This includes conducting feasibility studies, environmental impact assessments, and obtaining necessary permits and approvals.

- Extraction: The extraction of iron ore typically involves open-pit or underground mining methods, depending on the depth and accessibility of the deposit. Open-pit mining involves removing overburden (rock, soil, and vegetation) to expose the iron ore deposit, and then extracting the ore using heavy machinery, such as bulldozers, drills, and trucks. Underground mining involves creating tunnels to access the ore deposit and extracting the ore using underground mining equipment.

- Beneficiation: Once the iron ore is extracted, it needs to be processed to remove impurities and increase its iron content. This process, known as beneficiation, involves crushing, screening, washing, and magnetic separation or flotation to separate the iron ore from other minerals and impurities. Beneficiation processes can vary depending on the characteristics of the ore and the desired iron ore concentrate quality.

- Transportation: After beneficiation, the iron ore concentrate is typically transported to a processing plant or to a port for export. Transportation methods can include trucks, trains, or ships, depending on the location of the mine and the destination of the iron ore.

- Processing: At the processing plant, the iron ore concentrate may undergo further processing, such as pelletization or sintering, to create iron ore pellets or sinter, which are used in blast furnaces to produce iron and steel.

- Waste Management: Iron ore mining and processing can generate waste materials, such as overburden, tailings, and waste rock. Proper waste management practices, including storage, treatment, and disposal, are important to mitigate potential environmental impacts.

Mining and processing of iron ore can be complex and require careful planning, technical expertise, and adherence to environmental regulations and safety standards. The specific methods and processes used can vary depending on the type of iron ore deposit, the economics of extraction, and environmental considerations.

Uses of Iron Ore and Iron Products

Iron ore and iron products are used in a wide range of applications due to their versatility, strength, and abundance. Some of the major uses of iron ore and iron products include:

- Steel production: Iron ore is a key ingredient in the production of steel, which is one of the most widely used materials in the world. Steel is used in a variety of applications, including construction, automotive manufacturing, appliances, machinery, and transportation infrastructure.

- Construction: Iron and steel are used in various construction applications, such as in the construction of buildings, bridges, roads, and other infrastructure. Iron products, such as reinforcing bars (rebars) and structural steel, provide strength and durability to structures, making them essential materials in the construction industry.

- Manufacturing: Iron and steel are used in the manufacturing of a wide range of products, including machinery, equipment, vehicles, appliances, tools, and consumer goods. Iron products are used in various manufacturing processes, such as casting, forging, and machining, due to their high strength and machinability.

- Transportation: Iron and steel are used in the transportation industry for the production of vehicles, such as cars, trucks, trains, and ships. Iron and steel provide the necessary strength and structural integrity required for the transportation of goods and people.

- Energy production: Iron products are used in the production of energy, particularly in the form of wind turbines and electrical transformers. Wind turbines require large quantities of steel in their construction, while electrical transformers use iron cores for power transmission and distribution.

- Household appliances: Iron and steel are used in the manufacturing of various household appliances, such as refrigerators, washing machines, ovens, and stoves. Iron and steel provide strength and durability to these appliances, making them essential for daily household use.

- Packaging and containers: Iron and steel are used in the manufacturing of packaging materials, such as cans and containers for food and beverages. Iron and steel provide a durable and protective barrier, preserving the quality and safety of the packaged products.

- Tools and equipment: Iron and steel are used in the production of tools and equipment, such as hand tools, power tools, and heavy machinery. Iron and steel provide the necessary strength and durability required for these applications.

- Defense and military applications: Iron and steel are used in various defense and military applications, such as the production of armored vehicles, aircraft, ships, and weapons. Iron and steel provide the required strength, durability, and protection for these applications.

- Art and decorative applications: Iron and steel are used in art and decorative applications, such as sculptures, decorative elements in buildings, and furniture. Iron and steel provide a unique aesthetic appeal and versatility in artistic and decorative designs.

These are just some of the many uses of iron ore and iron products in various industries and applications. Iron and steel are essential materials that play a critical role in modern society and are used in a wide range of products and infrastructure that we rely on every day.

Market Trends and Challenges in the Iron Ore Industry

The iron ore industry is influenced by various market trends and faces several challenges that impact its operations and growth prospects. Some of the key market trends and challenges in the iron ore industry include:

- Global demand and supply dynamics: The demand for iron ore is closely linked to the global steel production, which in turn is influenced by economic growth, infrastructure development, and industrial activities. Demand for iron ore is typically cyclical, and fluctuations in demand can impact prices and production levels. Additionally, the supply of iron ore is influenced by factors such as mining output, production capacities, and transportation infrastructure, which can impact the availability and pricing of iron ore in the global market.

- Price volatility: Iron ore prices are subject to significant volatility due to various factors, including changes in demand and supply dynamics, geopolitical tensions, changes in government policies, and global economic conditions. Price volatility can impact the profitability of iron ore producers, investment decisions, and overall market sentiment.

- Environmental and sustainability concerns: The iron ore industry, like other extractive industries, faces increasing scrutiny and regulatory requirements related to environmental and sustainability concerns. This includes issues such as water management, air pollution, land rehabilitation, and greenhouse gas emissions. Compliance with environmental regulations can add costs and operational challenges for iron ore producers, and failure to meet these requirements can result in fines, penalties, and reputational risks.

- Technological advancements: Technological advancements in mining, processing, and transportation of iron ore can impact the efficiency, productivity, and cost-effectiveness of operations. Adoption of new technologies, such as automation, digitalization, and remote sensing, can improve safety, reduce costs, and increase production levels. However, technological advancements also require significant investments and may pose challenges related to workforce skills, regulatory compliance, and infrastructure requirements.

- Infrastructure challenges: The transportation of iron ore from mining sites to processing plants and export markets requires extensive transportation infrastructure, including railways, ports, and shipping vessels. Inadequate or outdated infrastructure can pose challenges to the efficient and cost-effective movement of iron ore, resulting in delays, increased transportation costs, and reduced competitiveness in the global market. Additionally, changing geopolitical dynamics and trade policies can impact transportation routes and logistics, affecting the flow of iron ore in the global market.

- Geopolitical and trade uncertainties: The iron ore industry is influenced by geopolitical and trade uncertainties, including changes in trade policies, tariffs, and export/import restrictions imposed by countries. These uncertainties can impact the demand, supply, and pricing of iron ore in the global market, affecting the profitability and growth prospects of iron ore producers.

- Safety and social responsibility: Safety and social responsibility are critical concerns in the iron ore industry. Ensuring the safety and well-being of workers, local communities, and other stakeholders is essential for sustainable operations. Additionally, the industry is increasingly expected to contribute to social and economic development in mining regions, including local employment, community engagement, and infrastructure development.

- Changing consumer preferences and substitution risks: Changes in consumer preferences and substitution risks can impact the demand for steel and, consequently, iron ore. For example, increased focus on sustainability and environmental concerns may lead to the adoption of alternative materials or technologies that could substitute steel in certain applications. This could potentially impact the demand for iron ore in the long term.

In summary, the iron ore industry faces various market trends and challenges that can impact its operations, profitability, and growth prospects. These challenges include global demand and supply dynamics, price volatility, environmental and sustainability concerns, technological advancements, infrastructure challenges, geopolitical and trade uncertainties, safety and social responsibility, and changing consumer preferences. Iron ore producers need to adapt to these market trends and challenges and develop strategies to ensure sustainable and profitable operations in a dynamic and competitive market environment.

Middle East and Africa Iron Ore Market

Middle East and Africa Iron Ore Market

Summary of Key Points about

Here is a summary of key points about iron ore:

- Definition and characteristics: Iron ore is a type of rock that contains iron minerals, which can be extracted and processed to produce iron and steel. It is typically found in the form of hematite, magnetite, and other iron-bearing minerals.

- Historical and modern uses: Iron has been used by humans for thousands of years, and it plays a critical role in modern society as a key ingredient in steel production. Iron and iron products are used in various industries, including construction, automotive, aerospace, energy, and manufacturing.

- Common iron ore minerals: Hematite and magnetite are the most common iron-bearing minerals in iron ore deposits. Hematite is typically red or reddish-brown in color and has a high iron content, while magnetite is black or dark gray and has a magnetic property.

- Occurrence and distribution: Iron ore deposits are found in various regions around the world, with major producers including Australia, Brazil, China, India, Russia, and the United States. Iron ore can occur in different geological formations, including banded iron formations, sedimentary iron ore deposits, and magmatic-hydrothermal iron ore deposits.

- Types of iron ore deposits: Iron ore deposits can be classified into several types based on their geological characteristics, including sedimentary iron ore deposits, magmatic-hydrothermal iron ore deposits, and metamorphic iron ore deposits. Each type has its unique characteristics in terms of mineralogy, ore texture, and formation processes.

- Mining and processing: Iron ore is typically mined through open-pit or underground mining methods, depending on the depth and location of the deposit. After extraction, iron ore is processed to remove impurities and obtain the desired iron content through crushing, grinding, magnetic separation, and other beneficiation techniques.

- Uses of iron ore and iron products: Iron ore is primarily used as a raw material in the production of iron and steel, which are used in various applications, including construction, transportation, machinery, appliances, and packaging. Iron and steel are essential materials for modern society and are widely used in infrastructure, manufacturing, and other industries.

- Market trends and challenges: The iron ore industry is influenced by global demand and supply dynamics, price volatility, environmental and sustainability concerns, technological advancements, infrastructure challenges, geopolitical and trade uncertainties, safety and social responsibility, and changing consumer preferences. Iron ore producers need to adapt to these market trends and challenges to ensure sustainable and profitable operations.

In summary, iron ore is a crucial raw material for the production of iron and steel, with significant global demand and supply dynamics, and faces various challenges and opportunities in the modern market environment. Understanding the characteristics, occurrence, mining, processing, and uses of iron ore, as well as the market trends and challenges, is essential for stakeholders in the iron ore industry.

Leave a Reply

Want to join the discussion?Feel free to contribute!